“Black Liquor” is a by-product of pulp from mills that make products from trees, such as paper. It is currently used to recover cooking chemicals and produce high-pressure steam used in the pulp and paper-making process. It is composed of different ingredients from these processes such as lignin, hemicellulose, sodium hydroxide (NaOH) and sodium sulfide (Na2S). The lignin compound in black liquor can be used to make biofuel but it can be expensive to produce and so fuel made from it is not very common.

However, and according to the International Energy Agency (IEA), the future of using black liquor as fuel is promising and it is seen as the fifth most important fuel on earth!

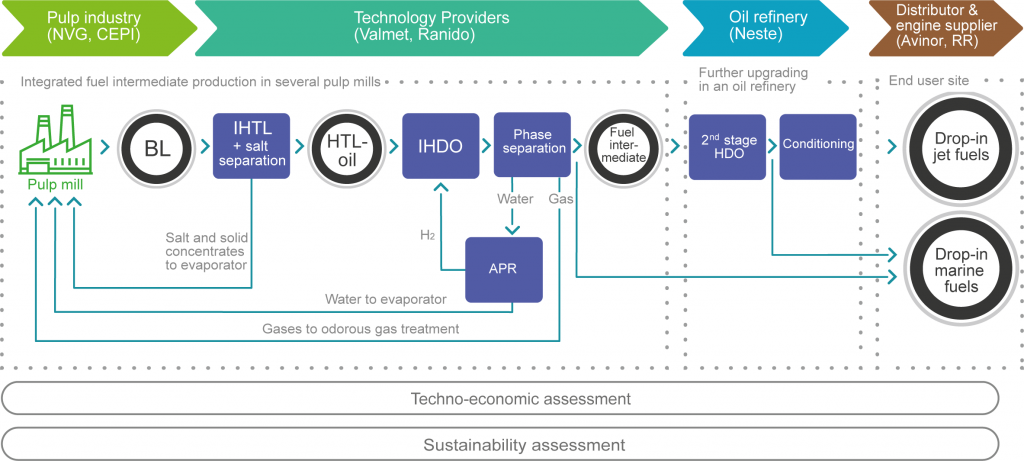

The bl2f process

The BL2F project will apply a process called “Integrated Hydrothermal Liquefaction” (IHTL) in the production stream. Using this process, there is no need to separate out the lignin which will lower costs and lower emissions. Estimates show that using black liquor could produce about 11 billion litres of advanced biofuels by 2050, and so it is aiming to become an important source for biofuels in Europe.

The result from the first step (an intermediate liquid phase) is then taken for further refining in a process called “Hydrothermal Hydrodeoxygenation” (HDO) and other feedback processes called“Aqueous Phase Reforming” (APR). These cyclical processes can produce energy for the pulp mill while also creating the fuel intermediate that will be upgraded in oil refineries.

The fuel developed in BL2F is a drop-in biofuel, this means that it can be used in the current plane and ship engines with no adjustments required.

From Pulp Mill to Biofuel: the BL2F way