Check out what the BL2F partners have been up to over the past 12 months

Work package 1: HTL-OIL Production

In Subtask 1.1. The black liquor sample characterizations (physical and chemical) were carried out by PSI and KIT and were completed by March 2021. The results have been stored and are available at Eduuni. In Subtask 1.2. The batch reactor tests at KIT were carried out in the period of April 2021 towards the end of 2021. The results have been stored and are available at Eduuni from spring 2022. The tests were carried out with a real black liquor sample and a “model” sample, developed from a mixture of commercial chemicals.

In Subtask 1.3 The aimed testings with a continuous HTL pilot plant have been delayed from the original planned timetable. Because the project needs biocrude oil samples in other work packages (WP3), it was decided to produce half a litre of biocrude oil from black liquor at SINTEF. The tests at SINTEF were completed in December 2021 -January 2022. The aim of half a litre of biocrude oil was not reached, but the samples withdrawn from the tests have been characterized at TAU during spring 2022. The pilot plant has been under commissioning during spring 2022. The preparations needed for testing at pulp mill (Setubal mill in Portugal) have been discussed in spring 2022. In Subtask 1.4 The location and requirements of laser on-line measurements have been planned and discussed during spring 2022 at TAU.

In Subtask 1.5 A thorough selection of materials and corrosion testing has been carried out at SINTEF. In March 2022, 4 different most potential candidates are available for further testing. The results have been stored and are available in the shared intranet.

In Subtask 1.6. One aim of the task has been to develop a scale-up mathematical model for HTL. First principles about how to build up the model were discussed in 2020 at TAU. The work has been an ongoing project, that would require measurement data from the HTL pilot plant at TAU Tampere campus. And therefore has been delayed. Also TAU has been checking the flowrates and compositions of pulp mill inlet and outlet streams, integrated with HTL production plant, mainly for WP4 purposes.

Work package 2: Salt Recovery & Side Stream Valorisation

Phase equilibria data has been obtained for the model salt solutions that replicate the composition of black liquor. It was found that increasing the concentration of NaOH and NaHS salts in the model salt solution had little impact on inducing Type 1 behaviour. Another strategy has been tested and proved to affect the phase equilibria of the salt mixture which showed Type 1 fluid phase behaviour. This approach allows a continuous extraction of the salt mixture from black liquor under hydrothermal conditions. In-house-made titanium grade 5 crucibles were found to be appropriate for HP-DSC (High Pressure Differential Scanning Calorimetry) measurements.

Work package 3: Upgrading & Application Testing

WP3 has focused so far on the development of catalyst and model component testing for first stage IHDO. VTT has performed experiments in a batch reactor with iso-eugenol as model compound and with model component mixtures. PSI has initiated the work with continuous system using equipment used for sulfur free feeds without any hydrogen gas feed. Simultaneously, PSI is developing and building another test rig enabling use of sulfur-rich feeds and H2 feed. The work has focused on model component studies so far.

Work package 4: Techno-Economic Assessment

Plausible options for the full integration of the HTL plant into the pulp mill has been identified and described through process flow diagrams. The main strategies for the integration include: 1) recirculation of the salts precipitate, solid residue and aqueous effluent back to the evaporators; 2) recirculation of residual gas streams back to the recovery boiler; 3) Direct heat extraction from the recovery boiler to a thermal oil for supplying the heat demand of the HTL plant. A preliminary estimation of the main flows from the HTL plant and the overall process performance of the pulp mill with integration of the HTL plant has also been calculated.

In preparation for the scale-up analysis, parametric models of the main systems involved in the HTL plant are being developed. These models evaluate the material and energy balances, individual equipment design and costs as a function of the HTL plant capacity.

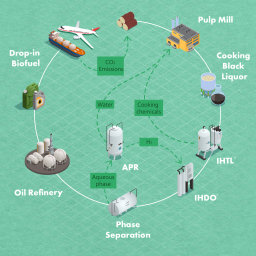

Work package 5: Sustainability Assessment

The activities have focused on mapping of the BL2F process, comprising of the Pulp Mill, the HTL plant, and the biorefinery, and material flows. The research has also focused on the development of the methodology of the Life Cycle Assessment (LCA) and circularity assessment. This includes scope definition, boundaries and data mapping, data requirements (inventory), review on suitable methodologies, frameworks and indicators for circularity measurement and assessment following the new ISO 59020, which is under consultation stage. The data collection process was started to identify primary data for the assessment. Assumptions based on expert’s knowledge and literature will be used when primary data is not available.

Work package 6: Market Potential & Exploitation

Deliverable 6.2 provided an analysis of the major trends that will influence the demand for biofuels in Europe in aviation and shipping by 2040 with the inputs of several experts from the biofuels and pulp and paper industries. Main factors impacting future biofuel demand were found : policies promoting biofuels in aviation and shipping, high cost competitivity of fossil fuels, cost competitivity of imported biofuels, and health crisis had the most impacts. A video is available on the website.

An Exploitation and IPR Plan was submitted in order to protect the main results and foresee their potential commercialisation.

LGI will provide Market Opportunities for the BL2F technology on 8 European countries. LGI led interviews with partners and is planning to conduct more with experts on market opportunities. If you’d like to be part of this study, feel free to contact us : Mathilde.legay@lgi-consulting.com

Work package 7: Dissemination and Communication

Aside from keeping the stakeholders updated on the project’s progress and activities, a campaign to inform and raise awareness of biofuels and the materials and processes used in BL2F was launched in the form of the “BL2F puzzle“. Audiences were invited to “solve the BL2F puzzle” which unveiled one piece at a time, from HTL to biocrudes to catalysts. Once all of the pieces were put together, the BL2F infographic was published which shows the whole process in an accessible and informative way!

On 15 & 22 March, the project held its Mid-Term workshop: Can pulp mills produce fuel in the future? Implementation of Hydrothermal Liquefaction for transport fuels. Participants from Europe and beyond attended the online event that presented the results of the project, alongside presentations on the biofuel value chain, catalyst development, feedstocks, and more. The partners also attended external events such as tcbiomass2022, EUBCE 2022, the Heat-to-Fuel final workshop and more.

Work package 8: Project coordination

Project coordination and day-to-day management of BL2F have been successful and the project has progressed according to the project plan. This is mainly due to the frequent project meetings and the application of the functional internal communication such as the Eduuni wiki platform. Members of the coordinating organisation, TAU, meet on a weekly basis to prepare project meetings and to regularly check the status of the project, for instance, the progress of the deliverables.

The periodic reporting, summarising the project activities over the first 24 months of the project, has been submitted on the 30th of May.